|

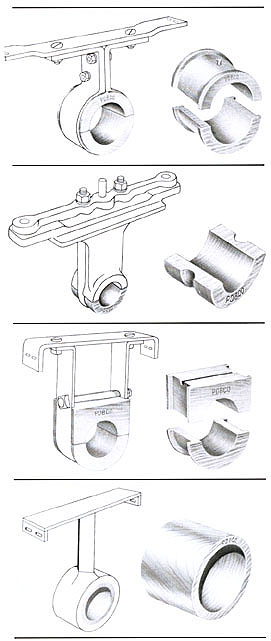

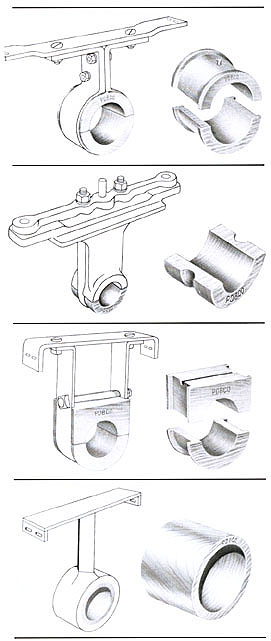

Pobco Bearings

n general, bearing support

stations on screw conveyors must be classified as severe service. The

materials handled are often corrosive and abrasive and sometimes moisture

laden. Conditions are encountered that can disintegrate conventional

bearings in extremely short time while also scoring and pitting the

journals.

In contrast, POBCO hanger bearings are unaffected by most

corrosive materials and work well even under moist conditions. When

abrasive materials are being handled, the small amount of particles that

reach the bearing surface become embedded in the POBCO

material without adversely affecting the bearings' performance. These

factors allow POBCO to handle a wide variety of materials

on this equipment.

POBCO hanger bearings are self-lubricating for life. They

are ideal for installation in screw conveyor assemblies, where the

bearings are usually inaccessible. The long life of POBCO

bearings and the elimination of excessive shaft wear are major factors in

reducing high maintenance costs and periodic shutdowns.

POBCO bearings are the quietest bearings made for screw

conveyors, whether operating slowly or at an accelerated pace. They

eliminate the noisy metal-to-metal sounds inherent is such machinery

employing metal bearings. The hanger bearings listed are the most commonly

used. Non-cataloged hanger bearing sizes and shapes, including sizes

larger then those listed, are available. |

|